-

Device for measuring the transmittance of smoke generated by cable combustion (smoke density)

2.1 Scope of applicationThis device is suitable for the requirements of the latest IEC61034-1997 or GB/T17651.1 and. 2-1998 "Measurement of Smoke Density of Cables or Optical Cables Burning under Specific Conditions", and is widely used for the transmittance test of low smoke halogen-free wires and cables. This system has a computer automatic data collection system, which automatically saves and prints raw data, fully meeting the requirements of the standard

2.2 Technical parameters

The measurable transmittance range is 0-100%, meeting the requirements of IEC61034-1997 or GB/T17651.1 and. 2-1998 standards.

The complete set of testing equipment includes the following equipment:

① Industrial control machine (Advantech Industrial Control)

② Light source system: DC power supply (accuracy 12 ± 0.01V), imported adjustable focal length light source; Aperture diameter ¥ 1.5M.

③ Receiving system: silicon photocell receiver with amplifier;

④ Data processing system: computer control system, software system supported by WINDOWS7, printer; The computer desktop displays the real-time temperature, transmittance, and combustion time curve relationship of the combustion chamber. The temperature thermocouple is K-type. The desktop has zero and full scale adjustments for system calibration.

⑤ A set of accessories (electric fan, sample holder, alcohol combustion tank, wind deflector, smoke exhaust system);

The electric fan meets the requirements of Chapter 7: Smoke Mixing in the standard. The standard requires an air volume of ¥ 300mm, which is adjustable from 7m ᶟ/min to 15m ᶟ/min

⑥ 27 m3 sealing test room: constructed by the demander according to the supplier's drawings.

" data-content=""> -

Device for measuring the transmittance of smoke generated by cable combustion (smoke density)

● 1 Scope of applicationThe CS type bundle combustion test device is applicable to the GB/T18380. (31-36) -2008 "Flame Test Settings for Cables and Optical Cables under Flame Conditions, Vertical Installation of Bundled Wire and Cable Flame Vertical Spread Test" standard. It is used for the flame retardant characteristics test of bundle flame retardant wires and cables, and also applies to the IEC60332-3-10:2000 standard.

Composition of 2 devices

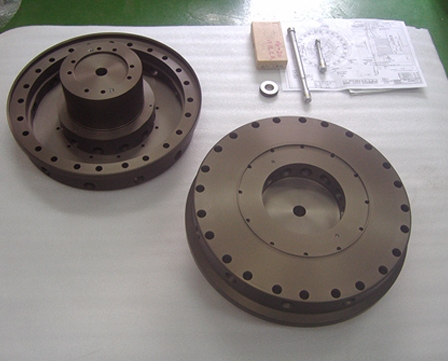

2.1 A bundle combustion test box with an automatic lifting ladder, including two combustion ladders (one standard ladder and one wide ladder) for tying the sample.

2.2 Two standard strip type spray lamps (including Venturi mixer) installed on the trolley.

2.3 A control cabinet with a dual air supply system, box temperature monitoring, combustion time control, ventilation and dust removal control.

2.4 A set of exhaust gas treatment system capable of dust removal and acid removal for combustion gases.

" data-content="">