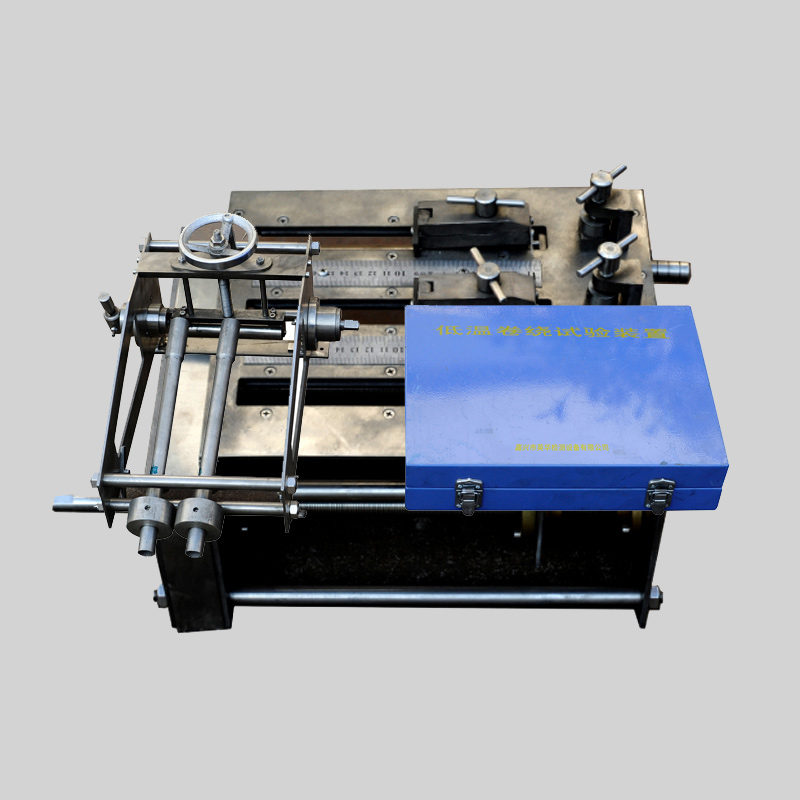

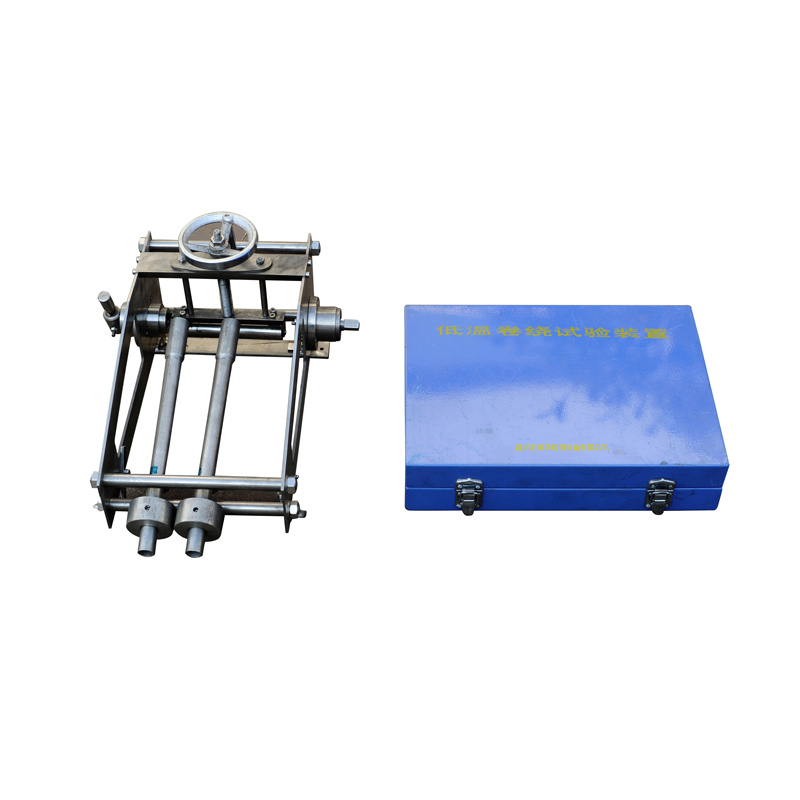

Durability Test Device for Core Marking of PN-I Insulated Cable

The structure and principle is that the step motor, synchronous wheel and Timing belt drive the C180mm cylinder. One end of the woven cotton belt is fixed around the cylinder, and the other end is laid flat on the surface of the sample and perpendicular to the axis of the sample. To ensure the tension of the cotton belt and the friction coefficient on the contact surface of the sample, the non fixed end of the cotton belt freely suspends a 2.2N counterweight, and the contact angle of the cotton belt on the arc surface of the sample is not less than 135 °. The one-way displacement of the cotton belt is 254+25mm, and the stroke in one cycle is not less than 508mm. The frequency of cotton cloth movement is 30+1 times/min. The C180mm cylinder can rotate 565mm once to meet the specific requirements for the test mentioned above. (The cylinder only needs to rotate about half a cycle)

Drive system: PIC programming is used to control the stepper application machine, and the device's start, stop, count, test frequency setting, and stepper operation speed are all operated on the touch screen. Automatically stop the machine when the friction frequency reaches the set number. Stepper motor, touch screen, PLC programming control, reliable performance, high stability, and convenient operation.